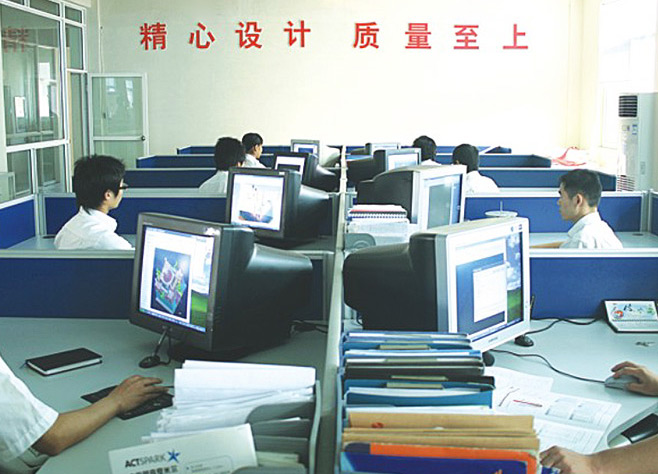

Design is the key to mold making

All of our designers have undergone rigorous professional training. They will consider all aspects of the design, such as product quality, product cost, manufacturing cycle, etc., to further ensure that your products have strong market competitiveness.

In order to ensure mold production, designers will test molds from various levels such as mold flow analysis, structural analysis, and production analysis. We have design software and sophisticated processing equipment that keeps pace with the times, and we are committed to providing our customers with the valuable new products. We provide customers with a variety of mold test reports, and reference information for all types of plastic molds. Fengzhan Mould strictly protects the intellectual property of its customers and will never leak information.

The company employs more than 200 people and covers a total area of over 26,000 square meters. The company has a series of advanced mold processing and testing equipment, CAD/CAE/CAM system, and has a team of technical knowledge and experienced technical backbone. The perfect combination of the two forms the development of Central Asia mold industry. The core strength of design, manufacturing and production.

Our main design and production software includes Unigraphics (3D), Pro/ENGINEER (3D) Solid Words (3D) Master CAM (3D) Cimatron (3D) Auto CAD (2D). We can receive a variety of documents, such as dwg, Dxf, x_t, prt, step, stl, IGS, etc.

Mold standard parts

Mould Steel: ASSAB (Sweden), DAIDO (Japan), FINKL(America),AUBERT & DUVAL(France), GS(Germany), LKM (China)

Mould Base: DME, HASCO, FUTABA, LKM.

Hot Runner: MOULD MASTER, Master TIP, HUSKY, HASCO, DME, YUDO, INCOE, THERMOPLAY

Standard Parts: DME, HASCO, NEAREST ANSI STANDARD, NEAREST DIN STANDARD, LKM

Texture: Mold-tech, Yick Sang, Tanazawa etc